Description

Air and Dirt Separator Manufacturer – Precision Storage Vessels

At Precision Storage Vessels, we are a leading Air & Dirt Separator Manufacturer serving industries across the UK, India, and the UAE. Our separators are engineered to efficiently remove entrained air and solid particles from hydronic systems, ensuring optimal performance and longevity of your equipment. We also specialize in Air Receivers designed to enhance compressed air systems with maximum efficiency and durability.

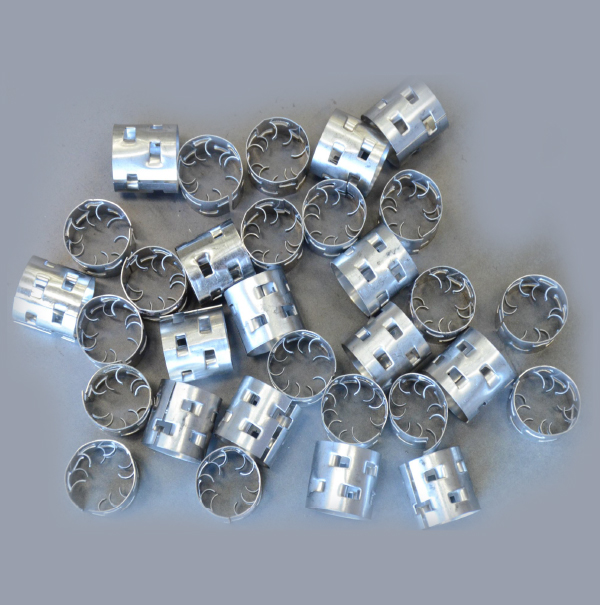

Constructed from high-quality carbon steel with stainless steel strainers, our separators are designed to handle standard working pressures up to 10 bar and temperatures up to 177°C, with options available up to 30 bar. The tangential design facilitates low-velocity vortex flow, effectively separating air and dirt with minimal pressure drop.

Our separators are fully customizable to meet specific system requirements and are compliant with ASME and CE standards. With a commitment to quality and customer satisfaction, we provide reliable solutions that enhance system efficiency and reduce maintenance costs.

FAQs About Air and Dirt Separator

- What is the Function of an Air and Dirt Separator?

An air & dirt separator removes entrained air and solid particles from hydronic systems, preventing issues like pump cavitation and corrosion, and improving system efficiency. - Why Choose Precision Storage Vessels for Air and Dirt Separators?

We offer high-quality, customizable separators built to international standards, ensuring optimal performance and durability in various industrial applications. - What Materials are Used in Your Separators?

Our separators are constructed from carbon steel with stainless steel strainers, providing durability and resistance to corrosion. - What are the Standard Operating Conditions for Your Separators?

Our separators operate at standard pressures up to 10 bar and temperatures up to 177°C, with options available up to 30 bar. - Can Your Separators be Customized?

Yes, we offer fully customizable separators to meet specific system requirements, ensuring compatibility and optimal performance.