Description

Indirect Hot Water Calorifiers Manufacturer – Precision Storage Vessels

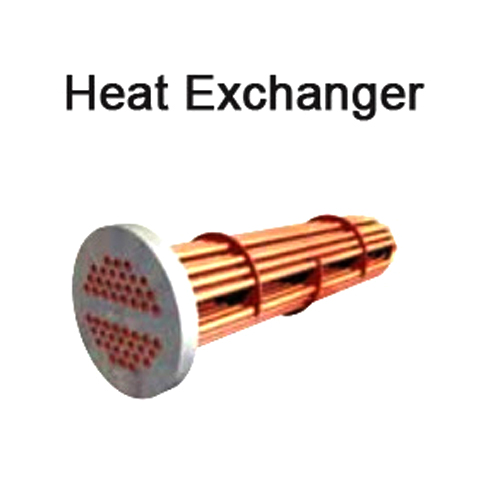

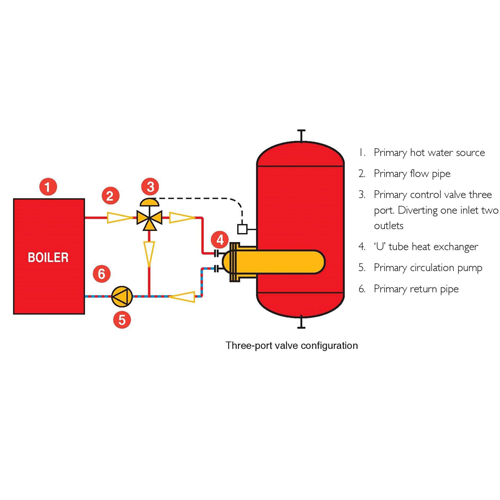

Precision Storage Vessels is a prominent Indirect Hot Water Calorifiers Manufacturer serving industries across the UK, India, and the UAE. Our calorifiers are designed to provide efficient and reliable hot water solutions for both domestic and industrial applications. Installed in hospitals, hotels, sports centers, and residential buildings, our calorifiers are ideal for sites with dedicated steam plants or hot water boilers. We also specialize in the manufacture of Plate Heat Exchangers, offering compact and efficient solutions for heat transfer in various thermal systems.

Constructed in accordance with ASME Code Section IV, our calorifiers are stamped and labeled for 125 PSI (8.6 BAR) as standard. We also design high-capacity water heaters as per British Standard BS 853:1996 or BS 5500:1997, or in accordance with Article 3.3 of the European Directive EEC/97/23 for pressure equipment.

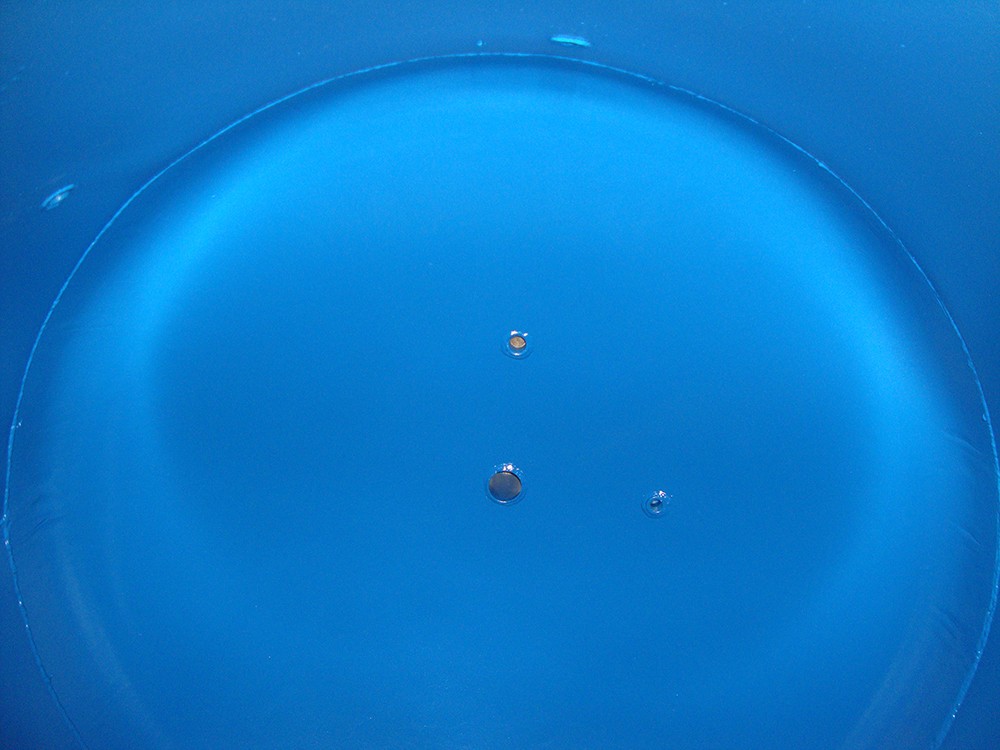

Our calorifiers feature a copper-lined vessel, where 1.2 to 1.6 mm thick copper sheets are tack-welded to a carbon steel shell and vacuum-formed to ensure a durable and corrosion-resistant interior. An anti-vacuum valve is fitted to prevent vacuum conditions during draining or unusual operating conditions.

With a focus on quality, safety, and performance, our calorifiers are engineered to meet the highest standards, providing reliable and efficient hot water solutions for various applications.

FAQs About Indirect Hot Water Calorifiers

- What is an indirect hot water calorifier?

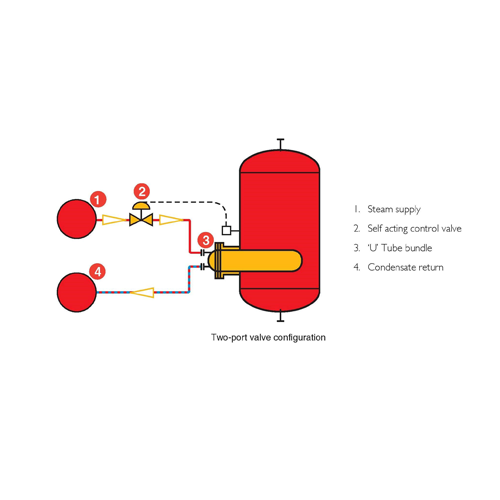

An indirect hot water calorifier is a storage tank that uses a heat exchanger coil to transfer heat from an external source, such as steam or hot water, to the stored water, providing a reliable hot water supply without the need for an integral burner. - What are the benefits of using a calorifier?

Calorifiers offer several advantages, including high heating coil duty, no need for electric power, reduced risk of shutdowns due to electrical issues, and no requirement for large investments in transformers or electric spares. - Are your calorifiers compliant with international standards?

Yes, our calorifiers are constructed in accordance with ASME Code Section IV and are stamped and labeled for 125 PSI (8.6 BAR) as standard. We also design high-capacity water heaters as per British Standard BS 853:1996 or BS 5500:1997, or in accordance with Article 3.3 of the European Directive EEC/97/23 for pressure equipment. - What materials are used in the construction of your calorifiers?

Our calorifiers feature a copper-lined vessel, where 1.2 to 1.6 mm thick copper sheets are tack-welded to a carbon steel shell and vacuum-formed to ensure a durable and corrosion-resistant interior. - Can your calorifiers be customized to meet specific requirements?

Yes, we offer customizable solutions to meet the specific requirements of our clients, providing reliable and efficient hot water solutions for various applications.