Description

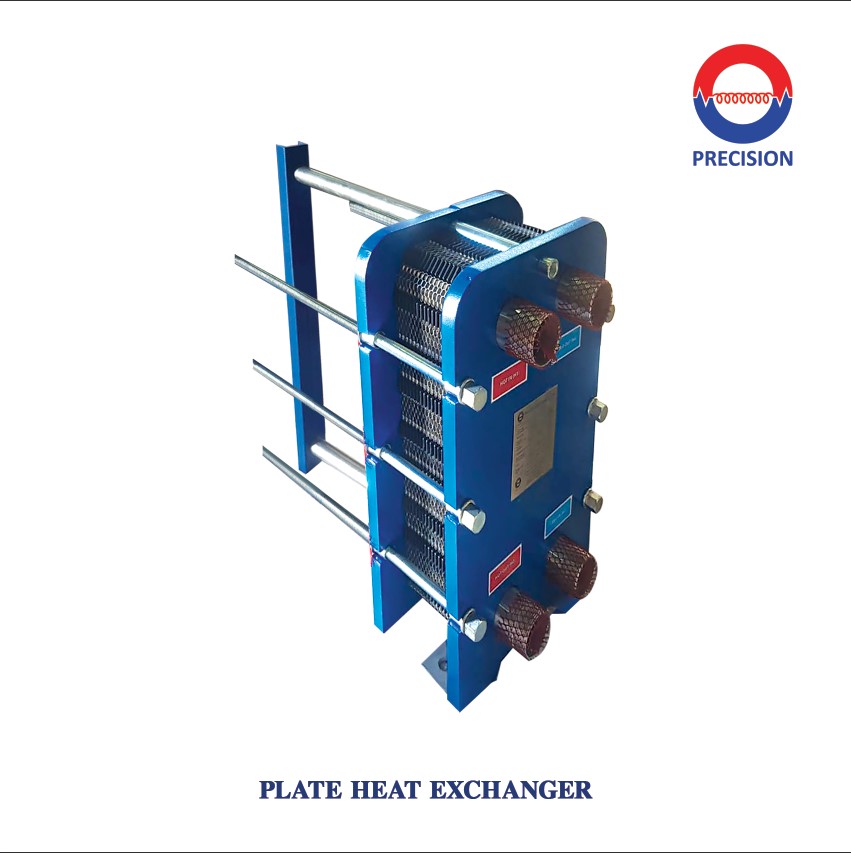

Plate Heat Exchanger Manufacturer – Precision Storage Vessels

Precision Storage Vessels is a trusted Plate Heat Exchanger Manufacturer serving industries across the UK, India, and the UAE. Our plate heat exchangers are designed for high-efficiency heat transfer in industrial processes, HVAC systems, and many other applications requiring thermal regulation. We also manufacture Indirect Hot Water Calorifiers, providing reliable and energy-efficient hot water solutions for a wide range of domestic and industrial uses.

Crafted using high-quality stainless steel and other corrosion-resistant materials, our plate heat exchangers provide excellent performance in both heating and cooling applications. Whether you’re looking for compact units for small-scale use or larger models for industrial systems, we offer custom solutions tailored to your specific needs.

Designed for easy maintenance and durability, our plate heat exchangers feature a modular construction with removable plates for quick inspection and cleaning. Each unit is built to international standards such as ASME and CE, ensuring reliability and longevity.

We prioritize innovation, energy efficiency, and superior customer service, offering products that enhance the operational efficiency of your systems.

FAQs About Plate Heat Exchanger

- What is a plate heat exchanger?

A plate heat exchanger is a device designed to transfer heat between two fluids through a series of plates, ensuring efficient heat exchange while minimizing space usage and improving system efficiency. - What industries use plate heat exchangers?

Plate heat exchangers are commonly used in industries such as HVAC, food and beverage, chemical processing, power generation, and pharmaceuticals, where heat transfer is essential. - How do I maintain a plate heat exchanger?

Regular maintenance involves cleaning the plates to remove deposits and scaling, inspecting seals and gaskets for damage, and checking for wear and tear on components. Proper maintenance ensures continued efficiency and longevity. - What are the advantages of plate heat exchangers over other types?

Plate heat exchangers offer high heat transfer efficiency, compact size, easy cleaning, and modular design, allowing them to be customized for various applications. They are also more energy-efficient compared to traditional shell-and-tube heat exchangers. - Can your plate heat exchangers be customized?

Yes, we offer fully customizable plate heat exchangers designed to meet your unique specifications, whether you require specific sizes, materials, or connection types.