High Capacity Electric Water Heaters

Electric Water Heater Manufacturer

Electric calorifiers are one of the easiest method of generating hot water for both domestic and industrial applications. Electric calorifiers are installed in hospitals, hotels, Sports Centres and General Residential Buildings.

Standards

ASME Code construction:- All tanks are constructed in accordance with ASME code section IV Stamped and labeled for 125 PSI (8.6 BAR) as Standard.

Precision also design electric calorifiers as per British Standard BS 853:1996, BS 5500:1997 or in accordance with Art 3.3 of the European Directive EEC/97/23 for pressure equipment.

Advantages

- Efficiency is maintained throughout the range of load. Even at part load all energy is converted into heat.

- Space requirements are minimum. Separate boiler fuel storage tanks are not required.

- Installation is simplified.

- The calorifier can be installed directly with the power supply.

- Maintenance is kept to a minimum.

- Electric calorifiers are clean.

- Electric calorifiers are extremely quiet.

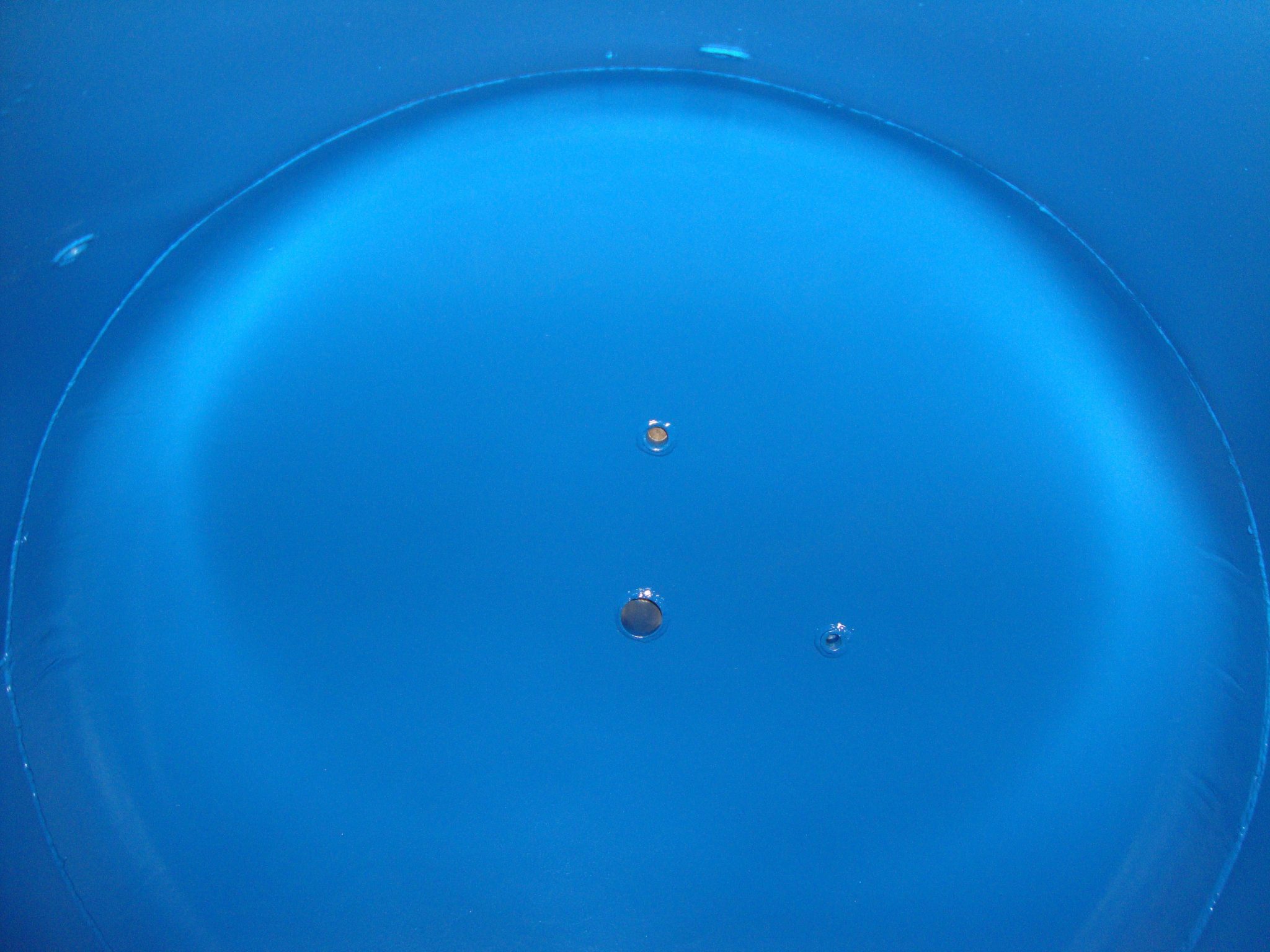

Copper Coat

Internally surfaces are first grit blasted and cleaned to a white metal finish and then, 100% pure solid copper is sprayed (by metallization process) uniformly in the tank. Once the tank surface is cooled, two coat of precision coat (polymerized coating) is applied to all internal surfaces above the copper coated tank. The tank are then forced cured at 95°C to form a glossy lining unaffected by thermal shock from 6°C to 100°C.Precision coat is approved by US department of agriculture and with NSF/61 certification for drinking water.

Copper lined vessel

It is uneconomical to manufacture pressure vessel with copper. To make it economical pressure vessels are manufactured in carbon steel, as per the required thickness and then lined with Copper sheets. Precision use 1.2 to 1.6 mm (above 5000 liter 1.6 mm) thick copper sheet which is tack welded to carbon steel shell and further pulled back by vacuum so that copper sheet is intact with a carbon steel shell. Anti vacuum valve is fitted with all copper lined shells as standard to prevent vacuum (partial /full) that occurs during drain or due to unusual operating conditions.

Standard – Shells

- Steel SA516 Gr-70

- Coating FDA approved Precision coat material

.

Heating Element ( Howden UK)

Heaters can be designed to operate in 3-phase, 415 volts, 50 HZ / 60 HZ supply. Precision uses two types of commonly used heating elements namely replaceable element and removable core element.

Replaceable Type

The elements on this type of immersion heater can be changed only after draining contents in the water heater.

Removable Core Type

Failed elements can be changed without draining the calorifier or removing the immersion heater from the shell. This saves time in changing the defective elements and with less down time. By this we can save the heated water without draining it.

Materials

Heating elements are available in copper, incoloy or Incoloy 825 which are suitable for any water conditions.